You have to use the right equipment for the job that is

suitable for the environmental conditions that it will be installed in.

With electrical equipment you have many options that are

perfect for the job that you are doing. On the other hand, you have unlimited

options for equipment that will get the job done, but will not last long enough

to get your money out of it.

Some companies will think that it is job security to install

the cheaper equipment. They often can under bid their competition by using

cheaper equipment also. I personally will not work for any company who uses

this type of philosophy, nor will I do that on my own projects around the house.

I work with electricians who think that using PVC conduit

instead of EMT conduit is somehow cheap or substandard. This simply is not true;

they both have a place. PVC isn’t just for underground either. Now I’m not saying

that using PVC all over the outside of buildings is good either. Like I said at

the beginning you need to use the right products for the location that they are

being installed.

For example, in salty environments EMT just does not hold up

to the corrosion and will rust out in a years’ time. PVC works great

underground but when its installed on the side of a house ran horizontally in

direct sunlight it will warp, expand, shrink and all the glued joints will pull

apart over time.

Then when exposed to direct sunlight try to only run it vertically for short distances. More straps with PVC is usually better in most cases. Painting the PVC conduit after install will also help make it blend in and stops the discoloration from the sun.

The main thing is to plan your install so that you have the least amount of exposed conduit possible.

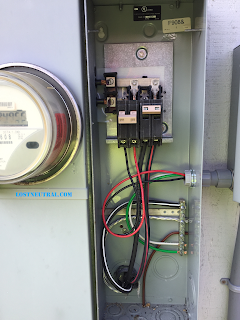

With combiner boxes and J-boxes they come in all sorts of weather/environment ratings. You can get them made from fiber glass, stainless and PVC. So, make sure you get the right one for the job.